Location: Pittsburgh, PA

Size: 1.45 million square feet

Cost: $294 million

Completion Date: September 2003

Inspired by the close suspension bridges, the David L. Lawrence Convention Center is charactereized by its clear-span roof constructed as a cable-stayed structure. The new project combines contemporary design with steel technology, influenced by the urban topography, the city's industrial history, and innovations in steel. Having achieved the USGBC LEED gold rating, the project is just one part of the city's continued emphasis on sustainable design. The facility features the largest column-free space through the investigation in long-span structures. The steel frame consists of major frames to the north and south of the building known as the bow and stern, resembling parts of a ship. The overall design incorporates 15 enormous cables strung over tall masts as seen in an image below.

Tuesday, January 23, 2007

Monday, January 22, 2007

Friday, January 19, 2007

Tidbit_Steel Innovations

I found a great summary of metal innovations in the book Steel & Beyond, as described on arcspace.com

Recent Advances:

Extremely light alloys

Hybrid constructions

Advanced methods for load calculations

Digital design and fabricataion

Adaptation of techniques from aeroplane design and ship building

It was also interesting to note that the last period of equivalent change occured during the mid 19th century when mass production of iron, steel, and glass developed.

Recent Advances:

Extremely light alloys

Hybrid constructions

Advanced methods for load calculations

Digital design and fabricataion

Adaptation of techniques from aeroplane design and ship building

It was also interesting to note that the last period of equivalent change occured during the mid 19th century when mass production of iron, steel, and glass developed.

Thursday, January 18, 2007

Tidbit_Pittsburgh Trip Plans

our site

u.s. steel tower (map)

david lawrence convention center (map)

pittsburgh children museum (map)

edgar thompson works (map) - only steel mill still operating in pittsburgh

u.s. steel tower (map)

david lawrence convention center (map)

pittsburgh children museum (map)

edgar thompson works (map) - only steel mill still operating in pittsburgh

Wednesday, January 17, 2007

Tidbit - Links

new york times - redevelopment advances on pittburgh's waterfront

pittsburgh tribune-review - on the waterfront

3 rivers 2nd nature website

pop city - changing the landscape of pittsburgh

EDGE studio - architects involved in remaking pittsburgh

south side works - new waterfront development downriver from our site

quantum IV building - proposed for the south side works

pittsburgh tribune-review - on the waterfront

3 rivers 2nd nature website

pop city - changing the landscape of pittsburgh

EDGE studio - architects involved in remaking pittsburgh

south side works - new waterfront development downriver from our site

quantum IV building - proposed for the south side works

History_Steel

General Steel History

Steel is a composition of iron and carbon. It is a material that has been used for thousands of years; however, it hasn’t been until the last century and a half that it has become a readily available material. The complex process of creating steel was far too expensive until Henry Bessemer patented his industry changing Bessemer process.

Steel begins with iron ore. Unfortunately, iron is not found in a pure form and thus must be extracted from ore. To do so, the ore must be smelted, meaning that it is melted to a liquid state and then other elements, mainly carbon, are combined with the molten ore to bond with and extract impurities in the ore. During this process, the iron absorbs a great amount of carbon—too much to create what would be considered steel. Here, the Bessemer process comes into play.

The Bessemer process uses large blast furnaces again to melt the carbon rich iron. Next, air is blasted through the mixture to burn on excess carbon. This is done in a controlled manner until only 0.2 – 1.7 % carbon remains. The presence of carbon in the iron hardens/stiffens the material; however, after a certain point, the mixture becomes brittle and useless for structure. It is this point in history where the steel industry becomes strongly tied with Pittsburgh and the concerns of our project discussed below.

Today the Bessemer process has been replaced by the Linz Donawitz Process (1968). The Linz Donawitz Process blasts pure oxygen through the molten iron rather than air, allowing for a more controlled final composition. Today there are many forms of steel created using the Linz Donawitz Process, below are a few of the most common:

Carbon Steel—90% of all steel, most often used for structural purposes

HSLA—high strength steel created by the addition of small amounts of

manganese

Low Alloy—steel with the addition of manganese, chrome, nickel or other

elements for harder thick steel

Stainless—steel with roughly 10% chromium to resist rust

Tool Steel—steel with a mixture of cobalt for hardening

Steel in Pittsburgh

Pittsburgh located in the Allegheny Mountains has shown significant production of metal goods since 1812 when the area was known for the production of iron and copper goods. The reason for this is that the mountain chain has a fair amount of iron ore especially. It was after the patent of the Bessemer process in 1955 that Pittsburgh made its rise as the steel capital of the country. The Bessemer process revolutionized the steel making process; steel was now affordable for mass production. This break through in the industry combined with the access to iron ore in the Pittsburgh region combined with the transportation opportunities in the region (the converging of the Allegheny, the Ohio and the Monongahela Rivers). Steel plants quickly appeared all along the rivers in the city. The Civil War and the demand for the production of steel war materials continued to fuel the industry in Pittsburgh and after the war, the rise of railroads showed no end to the demand for steel production. As the center of steel, railroads for transportation became increasingly important. In addition to the a long list of advantages for steel production in Pittsburgh, a steady wave of immigrants also found their way to Pittsburgh providing the labor needed to support the steel industry.

Around the late 1800’s Andrew Carnegie took the Pittsburgh steel industry to its peak. His efforts to merge some of the largest steel producers lead to somewhat of a monopoly on steel. In 1901 Carnegie sold his company to US Steel and at its peak around the turn of the century, Pittsburgh produced between 1/3 and ½ of the nation’s steel. Ironically, there were questions about the industry in Pittsburgh during this time as well. At this point, Pittsburgh had exhausted most of its iron ore supply. Most iron ore was arriving in Pittsburgh from Michigan and the rest of the Mid West. Steel plants in the Mid West began to rise and were able to offer lower prices because there were less shipping costs in the production of their steel. Still having the largest portion of steel production in the US, the industries in Pittsburgh were able to pass the Pittsburgh Plus plan in 1907 which created a price floor for steel and allowed the Pittsburgh steel industry remain competitive despite higher transportation costs. In 1924, the Pittsburgh Plus plan was ruled unconstitutional and was banned. It was here that the steel industry in Pittsburgh began to lose grip.

World War II provided another brief spike in steel production for Pittsburgh. Afterward, the industry made a steady decline unable to compete with industry in the West and Mid West. With the decline of the steel industry, Pittsburgh also saw a decline in population: in 1950 the city had 680 000 inhabitants, this figure dropped to 330 000 in 2000.

Pittsburgh after Steel

The steel industry left a permanent mark on Pittsburgh. After production surges in WWII pollution became a major issue in the city. Waste material destroyed the rivers and the industry lined rivers locked the city and its citizens away from the river fronts. In the 50’s the first large efforts to clean the industry were put into effect known as the Renaissance Project. Later in the 70’s a second Renaissance Project focused more on brining the citizens of Pittsburgh back to the river front. Today, we see continued efforts to revitalize the river fronts. Tourism, medical technologies, robotics, bio medical technologies and other high tech industries have replaced the steel industry.

Case Study_Footbridge, Amsterdam

the so-called 'python bridge' was designed and built as a part of the borneo/sporenburg development in amsterdam, master plan by west 8 architects. each home within this development is a 'patio house' where 30-50% of the space is left void to provide patios for introverted and personally expressive spaces within the tight urban fabric.

img_1.1 - python bridge

the footbridge is approx. 90 meters in length. it spans and active waterway, and its graceful curves allow for the passage of boats beneath. the steel truss, with t-shaped upper and lower cords and diagonal steel bracing is, and had been, a very common structural steel component. here, however, this basic form is morphed to create a more dynamic experience. in general, the bridge is very interesting because of how form, function, and experience are so closely tied.

for more photos of the bridge, click here.

img_1.1 - python bridge

the footbridge is approx. 90 meters in length. it spans and active waterway, and its graceful curves allow for the passage of boats beneath. the steel truss, with t-shaped upper and lower cords and diagonal steel bracing is, and had been, a very common structural steel component. here, however, this basic form is morphed to create a more dynamic experience. in general, the bridge is very interesting because of how form, function, and experience are so closely tied.

for more photos of the bridge, click here.

Tuesday, January 16, 2007

Case Study_Kalkriese Museum, Germany

the kalkriese museum and park in bramsche, germany was designed and built to mark the site of the battle between the roman legions and local barbarians. it makes use of specific material and structural qualities of steel to address important project concepts.

img_1.1 - museum

cor-ten steel is used to give the building a rust color to match surrounding buildings (which are not made of steel). more importantly, the cor-ten steel conveys the notion of time, which is important to the history of the site.

img_1.2 - museum / underside

this is the perspective the visitor is faced with just before entering the museum. the forced perspective and dark blur in the distance create a metaphor for time. also, steel is used to hold the building above the ground. steel enables this minimal structural scheme so the at the building can remain removed from the ground in a effort to acknowledge in archaeological importance of the ground plane.

img_1.3 - three pavilions

three pavilions are also situated throughout the site. they are built in the same manner as the main museum building. above, from left to right, the represent "Vision", "Listening", and "Understanding"; the function of each relates to its theme. for example, in the Listening pavilion, visitors can rotate the large trumpet in all directions to 'hear' the site. the pavilions allow the visitor to actively engage the site to gain a more personal awareness of it.

for more photos of the site, click here. for a pdf on cor-ten steel, click here.

img_1.1 - museum

cor-ten steel is used to give the building a rust color to match surrounding buildings (which are not made of steel). more importantly, the cor-ten steel conveys the notion of time, which is important to the history of the site.

img_1.2 - museum / underside

this is the perspective the visitor is faced with just before entering the museum. the forced perspective and dark blur in the distance create a metaphor for time. also, steel is used to hold the building above the ground. steel enables this minimal structural scheme so the at the building can remain removed from the ground in a effort to acknowledge in archaeological importance of the ground plane.

img_1.3 - three pavilions

three pavilions are also situated throughout the site. they are built in the same manner as the main museum building. above, from left to right, the represent "Vision", "Listening", and "Understanding"; the function of each relates to its theme. for example, in the Listening pavilion, visitors can rotate the large trumpet in all directions to 'hear' the site. the pavilions allow the visitor to actively engage the site to gain a more personal awareness of it.

for more photos of the site, click here. for a pdf on cor-ten steel, click here.

Case Study_Building with Steel

"We could reproduce the angles of Picasso; we could experiment with steel as the painters did with paint"

- Steel Rigid Frame Manual: Design and Construction

My steel research began by looking at welding diagrams and gigantic rigid steel frames. I looked up every steel manual in the Architecture library. Although interesting, and certainly worthwhile, I-beam specifications and steel pipe thicknesses were not going to be enough to fully introduce me to the possibilities of steel construction.

My first interesting find was some information on two of the most basic ways of joining steel components; riveting and welding. Although riveting possesses a rigid aesthetic and creates powerful forms with thick plates and massive nuts and bolts, the bottom line turns out to be that it is in most cases just not practical. Not only does welding cut down on the amount of steel necessary to build, but construction is quicker and far less limited. Welded steel joints share every advantage that rivet construction does plus much more.

For example, the riveted plates in the above image stand out in an almost overwhelming sense. However, if you look closely you will notice the weld symbol and the barely noticeable seam between the two plates. Welded joints, if done correctly, can go almost unnoticed.

It was not until I began looking at more contemporary steel structures that I noticed how endless the possibilities of steel construction could be, and how fast the use of steel in building has advanced. First, take a look to the detail below at Crown Hall, Mies' architecture building on the IIT campus finished in 1956. Mies uses welded plate girders to span the entire width of the roof.

Less than 50 years later, Renzo Piano is using steel trusses to span the entire width of an airport, as well as creating flowing forms from tubular steel.

Lastly, take a look to a detail done by Richard Rogers that I feel utilized the potential of steel to quite an extent. The below detail uses welds, rivets, tension cables, steel piping, plate steel, and pin connections that allow for movement all in one structural element.

In conclusion, it seems that steel is a material that lends itself to innovative use. With today's technology steel fabrication is endless, from the smallest details and joints to trusses that span the length of a building. My imagination before flipping through a stack of books stopped around prefabricated steel components, but has ended in a world where steel can be welded at any angle and bent or cut into almost any shape. I think one of the most promising aspects of the semester ahead of us is the opportunity to work with no limits and create a building with "custom" steel structure and details.

- Steel Rigid Frame Manual: Design and Construction

My steel research began by looking at welding diagrams and gigantic rigid steel frames. I looked up every steel manual in the Architecture library. Although interesting, and certainly worthwhile, I-beam specifications and steel pipe thicknesses were not going to be enough to fully introduce me to the possibilities of steel construction.

My first interesting find was some information on two of the most basic ways of joining steel components; riveting and welding. Although riveting possesses a rigid aesthetic and creates powerful forms with thick plates and massive nuts and bolts, the bottom line turns out to be that it is in most cases just not practical. Not only does welding cut down on the amount of steel necessary to build, but construction is quicker and far less limited. Welded steel joints share every advantage that rivet construction does plus much more.

For example, the riveted plates in the above image stand out in an almost overwhelming sense. However, if you look closely you will notice the weld symbol and the barely noticeable seam between the two plates. Welded joints, if done correctly, can go almost unnoticed.

It was not until I began looking at more contemporary steel structures that I noticed how endless the possibilities of steel construction could be, and how fast the use of steel in building has advanced. First, take a look to the detail below at Crown Hall, Mies' architecture building on the IIT campus finished in 1956. Mies uses welded plate girders to span the entire width of the roof.

Less than 50 years later, Renzo Piano is using steel trusses to span the entire width of an airport, as well as creating flowing forms from tubular steel.

The innovation does not stop here either. Along with Renzo Piano, Richard Rogers and Frank Gehry are using steel to create spectacular details and outrageous forms, unimaginable just 50 years ago. The framework in Gehry's Walt Disney Concert Hall is almost entirely made from steel. The image below shows the structure before being clad in its titanium finish.

Lastly, take a look to a detail done by Richard Rogers that I feel utilized the potential of steel to quite an extent. The below detail uses welds, rivets, tension cables, steel piping, plate steel, and pin connections that allow for movement all in one structural element.

In conclusion, it seems that steel is a material that lends itself to innovative use. With today's technology steel fabrication is endless, from the smallest details and joints to trusses that span the length of a building. My imagination before flipping through a stack of books stopped around prefabricated steel components, but has ended in a world where steel can be welded at any angle and bent or cut into almost any shape. I think one of the most promising aspects of the semester ahead of us is the opportunity to work with no limits and create a building with "custom" steel structure and details.

Case Study_Museums

I have found some interesting case studies and information on the design of museums pertaining to the purpose and philosophy behind museum design, ways in which steel is used in contemporary museums, and instances of museums located on waterfronts.

In Reshaping Museum Space, the authors discuss the purpose of museums. Different things they bring up:

-Quote from The Architecture of the Museum

I think this quote is relevant to the Steel Museum because we are in a sense preserving an entire history of steel production in Pittsburgh that is quickly being encroached upon, and in danger of being forgotten. It is a big responsibility to capture this history that has had such a significant impact on the city in one building.

This brings up another issue--the idea of a museum "embodying" the essence of its purpose. The Jewish Museum in Berlin (image below), though criticized for this very reason, achieves this embodiment succesfully. Critics claim that the building puts the contents at an inferior level by overpowering the user and its exhibitions; however, what is succesful about the building, in my opinion, is that it captures the feeling of mourning, suffering, and loss in its jagged exterior and form.

Jewish Museum-Berlin, Libeskind

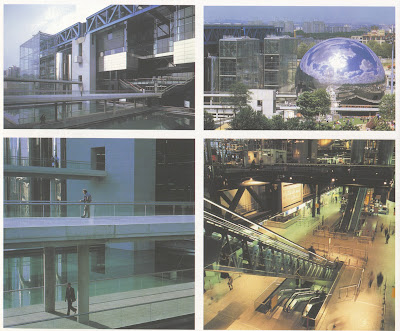

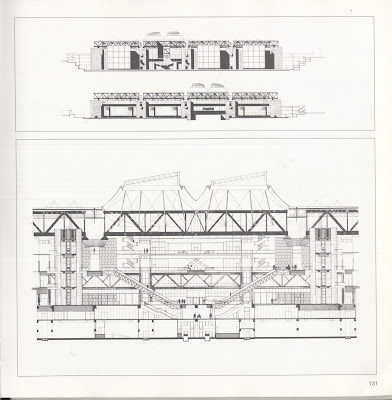

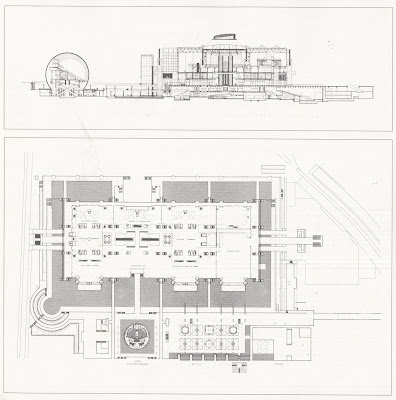

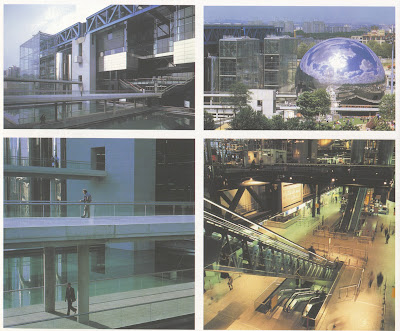

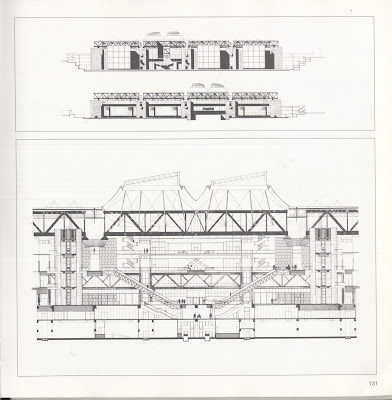

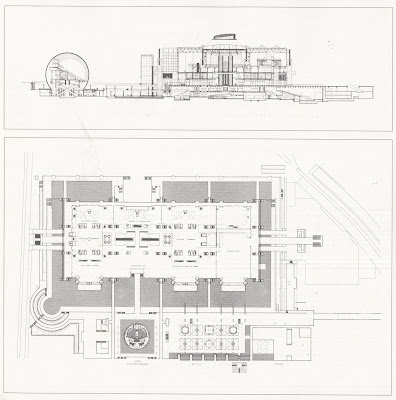

One of the more relevant museums in terms of character I found was the National Museum of Science, Technology, and Industry in Paris, which is part of the Parc de la Villette.

National Museum of Science, Technology, and Industry- Paris, Faisilber Architect

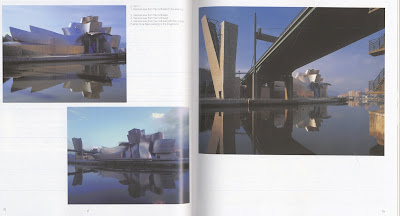

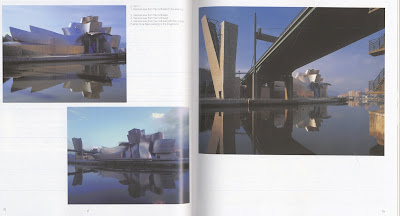

The Guggenheim in Bilbao is interesting in its existence as an iconic building on the waterfront and its relation to the urban fabric.

Guggenheim-Bilbao, Gehry

Milwauke Museum of Art- Calatrava

Kiasma Museum of Contemporary Art- Helsinki, Steven Holl Architect

Modern Art Museum-Fort Worth, Tadao Ando Architect

Sculptural use of Cor-ten steel.

Imperial War Museum North-Manchester, Libeskind

In Reshaping Museum Space, the authors discuss the purpose of museums. Different things they bring up:

- the museum should be built with the community's needs in mind

- which is more important, the "content" or the "container"?

- the museum should be a social and cultural symbol

- circulation should be carefully considered from the beginning

- the "majesty of the building [should] correspond to the importance of the production it holds...."

-Quote from The Architecture of the Museum

I think this quote is relevant to the Steel Museum because we are in a sense preserving an entire history of steel production in Pittsburgh that is quickly being encroached upon, and in danger of being forgotten. It is a big responsibility to capture this history that has had such a significant impact on the city in one building.

This brings up another issue--the idea of a museum "embodying" the essence of its purpose. The Jewish Museum in Berlin (image below), though criticized for this very reason, achieves this embodiment succesfully. Critics claim that the building puts the contents at an inferior level by overpowering the user and its exhibitions; however, what is succesful about the building, in my opinion, is that it captures the feeling of mourning, suffering, and loss in its jagged exterior and form.

Jewish Museum-Berlin, Libeskind

One of the more relevant museums in terms of character I found was the National Museum of Science, Technology, and Industry in Paris, which is part of the Parc de la Villette.

National Museum of Science, Technology, and Industry- Paris, Faisilber Architect

The Guggenheim in Bilbao is interesting in its existence as an iconic building on the waterfront and its relation to the urban fabric.

Guggenheim-Bilbao, Gehry

Milwauke Museum of Art- Calatrava

Kiasma Museum of Contemporary Art- Helsinki, Steven Holl Architect

Modern Art Museum-Fort Worth, Tadao Ando Architect

Sculptural use of Cor-ten steel.

Imperial War Museum North-Manchester, Libeskind

Subscribe to:

Posts (Atom)